ادامه مطلب

Applications in Industry

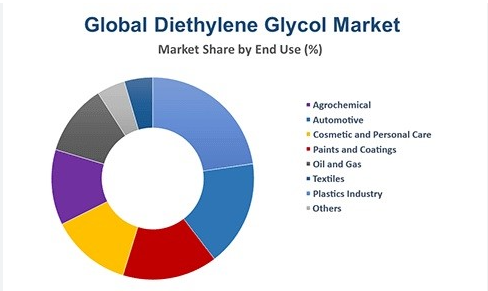

Diethylene glycol (DEG) is a versatile compound widely used across various industries due to its unique chemical properties and functional capabilities. Its applications range from pharmaceuticals to plastics, making it an integral component in numerous products and processes. Overview of Industries Utilizing Diethylene Glycol 1. Pharmaceuticals: DEG serves as a solvent for active pharmaceutical ingredients (APIs) and plays a critical role in drug formulation. It aids in the solubilization of …